Understanding Heat Management and Material Response in Laser Welding

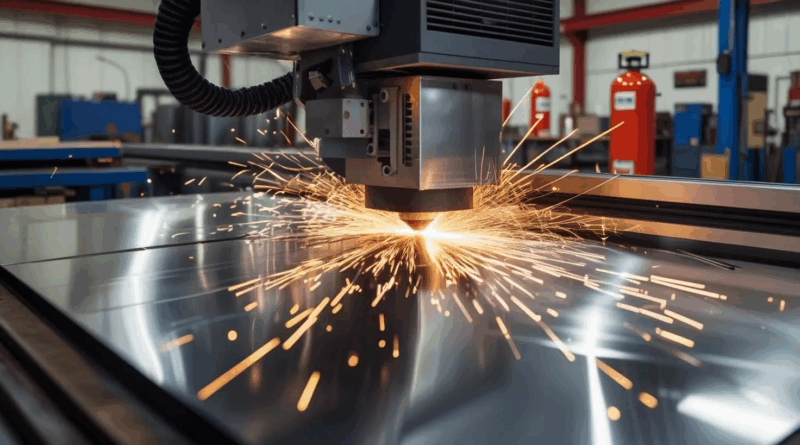

When you’re managing precision welding operations, one variable dominates every decision—heat control. Laser welding brings exceptional focus and energy density, producing narrow welds and minimal distortion. But that precision only pays off when you fully understand how heat affects material behavior.

In modern manufacturing, where microstructure and mechanical integrity determine performance, the laser welder has become indispensable. This article explains how heat is generated and managed during welding, how different materials respond, and what to look for in equipment that maintains ideal thermal control throughout the process.

Common pain points addressed:

- Difficulty maintaining weld consistency due to uncontrolled heat input.

- Material distortion and cracking from uneven cooling.

- Reduced joint strength or fatigue life from poor HAZ (heat-affected zone) control.

Fundamentals of Heat Input in Laser Welding

Heat Density and Thermal Gradient

Laser beams deliver intense, localized energy—up to 1 MW/cm² in power density. This creates steep thermal gradients, heating and cooling the material rapidly. The rate of heat transfer directly affects the size of the heat-affected zone (HAZ) and the level of distortion that follows.

In simple terms, more concentrated energy equals faster melting and cooling. Managing that balance is key to achieving strong, clean welds with minimal stress.

Modes of Heat Control: Conduction vs. Keyhole

There are two primary modes of laser welding:

- Conduction mode: The laser heats the surface until it melts but doesn’t vaporize. This results in shallow penetration and a smaller HAZ—ideal for thin materials or micro-welding.

- Keyhole mode: At higher power, the laser vaporizes material to create a deep cavity (“keyhole”) that allows deeper penetration. While effective for thicker joints, it produces a larger molten pool and requires precise control to avoid distortion or defects.

Impact of Pulse and Beam Parameters

Pulse control is one of your most powerful tools. Pulsed or modulated laser operation allows you to limit heat input and fine-tune cooling rates. Adjusting beam focus, wavelength, and absorption can drastically influence how heat spreads through the material.

For example, a tightly focused beam produces narrow, deep welds, while a slightly defocused beam distributes heat more evenly—reducing risk in reflective or thermally conductive metals like aluminum and copper.

Material Behavior Under Laser Welding Thermal Cycles

Microstructural Changes in the HAZ

The HAZ is where the real story unfolds. Even without melting, materials here experience grain growth, phase changes, or softening due to temperature exposure.

- High-strength low-alloy (HSLA) steels may soften under laser welding if cooling rates aren’t carefully managed.

- Austenitic stainless steels resist cracking but can show sensitization (chromium depletion) with prolonged heating.

By controlling beam parameters, you can minimize these effects and retain desired microstructures.

Mechanical Property Effects

Changes in microstructure naturally impact strength, hardness, and ductility. The fast heating and cooling in laser welding can create residual stresses, sometimes leading to brittleness or distortion. Balancing the energy input is crucial to maintaining weld toughness while avoiding stress cracking.

Material-Specific Considerations

Different materials behave differently under the laser’s thermal cycle:

- Aluminum and copper: High thermal conductivity spreads heat, widening the HAZ.

- Dual-phase steels: Their martensitic phases demand tight thermal control to avoid soft zones.

- Titanium and nickel alloys: Require inert shielding to prevent oxidation under high heat.

Understanding each material’s thermal response helps you fine-tune your laser welder for the best performance.

Heat Management Strategies and Process Control

Parameter Optimization

To maintain control, optimize:

- Laser power and speed: Lower power or faster travel minimizes heat buildup.

- Pulse shaping: Reduces peak temperature and cools between pulses.

- Beam focus: Keeps energy localized and reduces heat spread.

- Wavelength selection: Improves absorption efficiency in different metals.

These adjustments work together to achieve smaller HAZs and more stable welds.

Pre- and Post-Weld Thermal Treatment

For complex or thick materials, preheating and post-weld heat treatment (PWHT) stabilize the microstructure. This reduces the risk of cracking and improves fatigue resistance, particularly in steels or high-strength alloys.

Fixtures, Clamping, and Heat Sinks

Mechanical support plays a major role in heat control. Proper clamping minimizes expansion and contraction mismatch, while heat sinks and cooling fixtures prevent excessive heat accumulation. These measures keep parts dimensionally stable, even under rapid temperature changes.

Monitoring and Measurement Techniques

Modern systems use real-time sensors to monitor heat input, detect changes in temperature distribution, and adjust laser power instantly. You can measure the resulting HAZ through:

- Microhardness testing to identify soft or hard zones.

- Metallographic analysis for grain size and phase structure.

- Infrared imaging to map heat spread during production.

This data-driven control ensures repeatable, high-quality joints.

Impacts on Joint Quality, Performance & Equipment Selection

Joint Integrity and Durability

The HAZ directly affects joint performance. Controlled heat input leads to consistent microstructure, better fatigue resistance, and minimal distortion. Conversely, overheating can cause soft zones, porosity, or cracks that shorten service life.

Equipment Specification Considerations

When evaluating a laser welder, focus on:

- Beam quality and power control: Determines energy precision.

- Pulse options: Enables fine-tuning of thermal input.

- Cooling systems: Essential for consistent performance and component protection.

- Integrated sensors: Allow adaptive process control in real time.

Material Compatibility and Process Flexibility

Your system should adapt easily to different metals, joint types, and thicknesses. High flexibility reduces setup changes and ensures predictable results across varied applications.

Maintenance, Calibration, and Long-Term Performance

Stable heat control depends on clean optics, efficient cooling, and regular calibration. Neglecting these elements can lead to unstable weld penetration and variable results. Preventive maintenance keeps the system running within the designed thermal tolerances.

Why Choose Denaliweld’s Solutions

For manufacturers focused on precision heat control and repeatable weld quality, Denaliweld provides laser welder systems built for consistency. Their equipment combines high beam quality, precise power modulation, and adaptive thermal control, helping you reduce HAZ size and distortion across materials.

Whether you’re welding aluminum battery enclosures, precision steel components, or reflective alloys, Denaliweld’s design flexibility ensures stable, efficient, and reliable results—making it a future-proof investment for high-performance production.

Conclusion

Mastering heat control in laser welding isn’t just about avoiding distortion—it’s about unlocking material performance. By understanding how thermal cycles affect microstructure and strength, you can design processes that deliver consistent, durable joints.

Choosing the right laser welder is the first step. Look for systems with robust beam control, precise pulse modulation, and intelligent monitoring. With the right setup—like those from Denaliweld—you can achieve stronger welds, smaller HAZs, and greater efficiency across every production run.

- Understanding Heat Management and Material Response in Laser Welding

- Weber Grillvorführung – Ultimate Guide to Expert Grill Demonstrations!

- Asbestlint – Complete Guide to Understanding, Safety, and Removal!

- Prostadine colibrim – Natural Support for Prostate Health

- What Is Test Coverage And What Should You Know About It?